What is a ball valve?

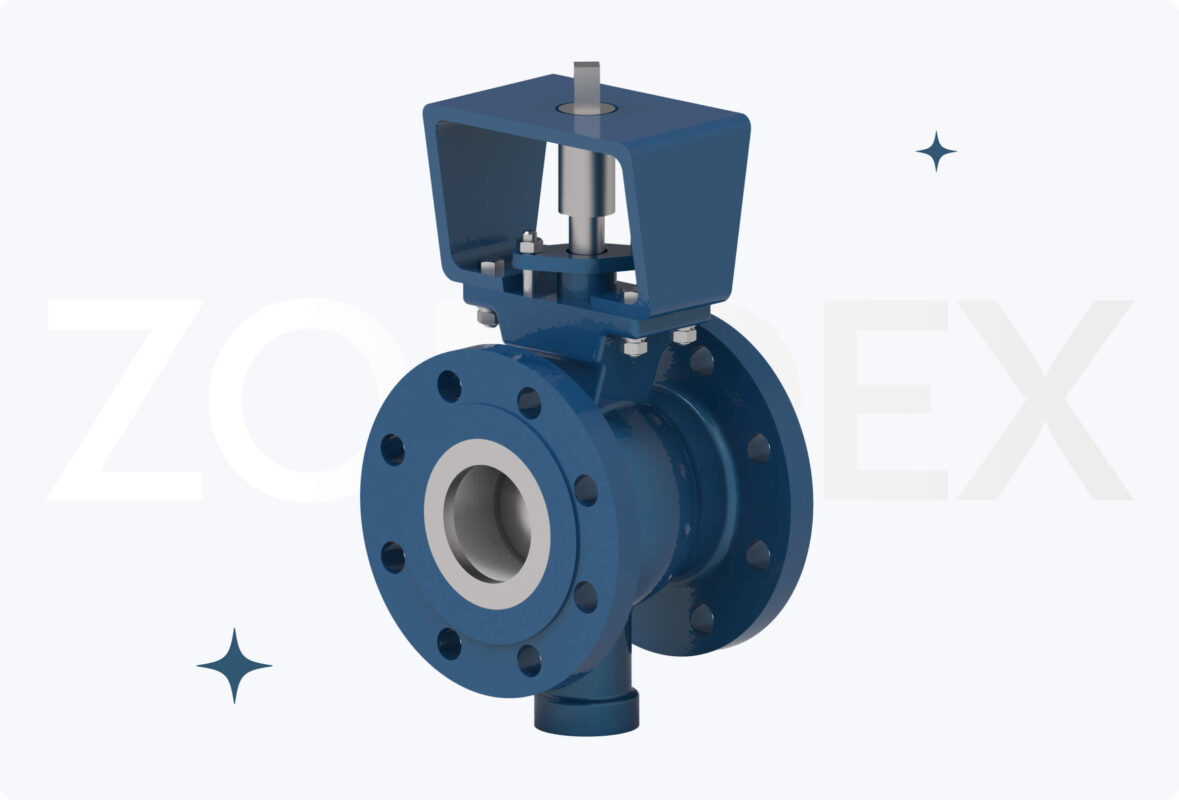

A ball valve is one of the most commonly used shut-off valves in industrial, water supply, gas, and domestic installations. Its key component is a spherical mechanism with a through bore that, when rotated around its axis, opens or closes the flow of the medium.

Ball valves are valued for their simplicity, durability, and quick operation—a quarter turn (90°) is enough to fully open or close the valve.

How does a ball valve work?

The operating principle of a ball valve is based on a rotating ball with a bore through its center. When the bore is aligned with the flow direction, the medium flows freely. When the ball is rotated 90°, the bore is positioned perpendicular to the flow, blocking it.

Ball valves can be operated manually (using a lever) or automatically through electric, pneumatic, or hydraulic actuators. Due to their low operating torque, ball valves are ideal for applications requiring quick response times.

Advantages of ball valves

Ball valves offer numerous operational benefits:

Quick opening and closing – requires only a 90° rotation

High tightness – thanks to precision seals (PTFE, Teflon)

Long service life – resistant to corrosion and wear

Low flow resistance – full bore design with no reduction in diameter

Compact size and easy installation – ideal for confined spaces

Versatile operation – suitable for liquids, gases, steam, and aggressive media

Applications of ball valves

Ball valves are used in:

Water and heating installations

Gas networks, LPG, and compressed air systems

Chemical and food industries

Industrial automation systems

Hazardous areas (ATEX zones)

Oil, fuel, and refrigeration installations

Summary

Ball valves are versatile, durable, and easy-to-operate components of industrial piping systems. Thanks to their compact design, high tightness, and ability to operate across a wide range of temperatures and pressures, they find application in nearly every technical industry. By choosing Zondex ball valves, you invest in reliability, precision, and user comfort.

Models and production range of Zondex ball valves

Zondex Engineering offers a wide range of ball valve models, including the following models:

401, 402, 403, 404, 405, 406, 407, 408, 409, 410, 411, 412, 413, 414, 415, 416, 417, 418, 419, 420, 421, 422, 423, 424, 425, 426, 427, 428.

Available nominal diameters: DN 15 to DN 1200

Working pressure range: PN 16 (1.6 MPa) to PN 64 (6.4 MPa)

Valve bodies can be manufactured in various materials depending on the application:

🔹 Ductile iron

– EN-GJS-400-15 / GGG40

🔹 Carbon steels

– ASTM A216 WCB, A105, Q235 / P235, A216 WCC

🔹 Low alloy steels

– ASTM A352 LCC, LCB, LCI, LC2

– ASTM A217 WC6, WC9

– ASTM A182 F11

– ASTM A350 LF1 / LF2 / LF3

🔹 Stainless steels (corrosion-resistant)

– A351 CF8 / AISI 304 / A182 F304

– A351 CF8M / AISI 316 / A182 F316

– A351 CF3 / AISI 304L / A182 F304L

– A351 CF3M / AISI 316L

– AISI 904L, AISI 316Ti, AISI 321, AISI 310S

🔹 Special steels (duplex)

– Duplex 2205

– Duplex 2507