What is a butterfly valve?

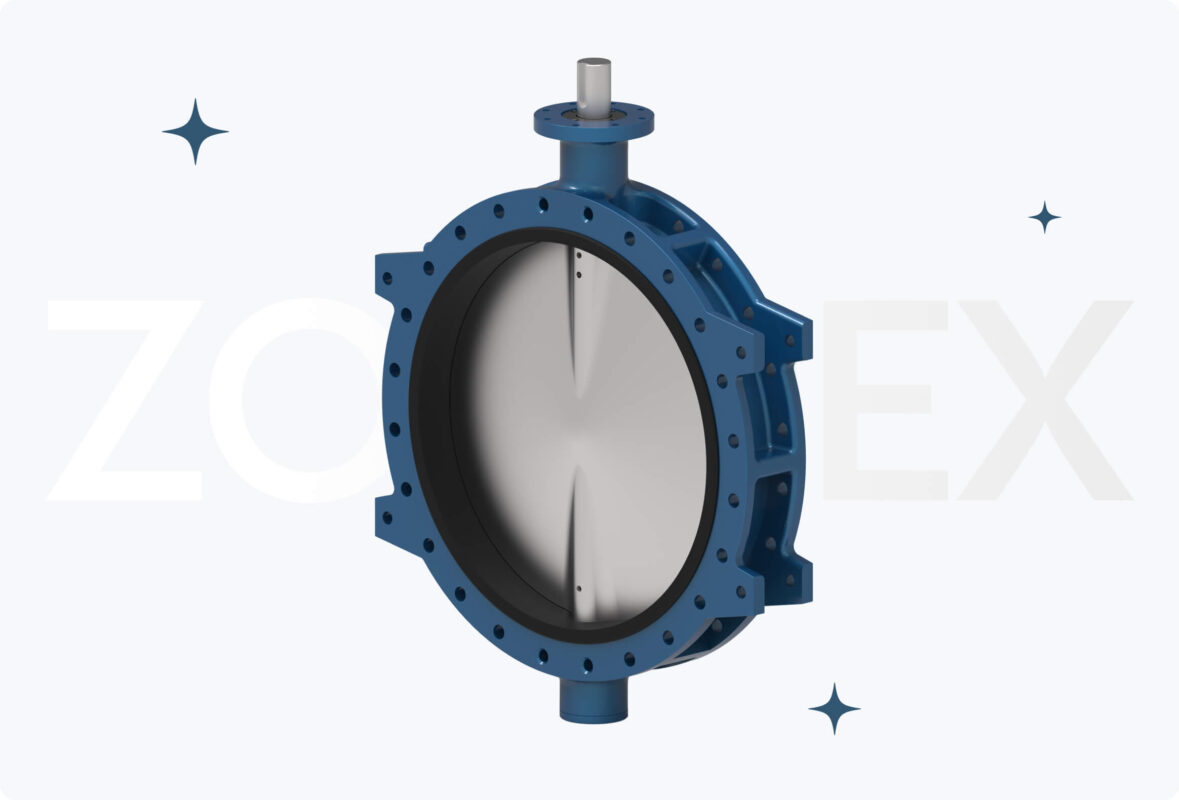

A butterfly valve is a shut-off valve used to regulate or isolate the flow of liquids and gases in pipelines. Its name comes from the characteristic rotating disc, which resembles the shape of a butterfly’s wing.

Thanks to its compact design, butterfly valves are widely used in industrial, water supply, ventilation, and power installations. They perform excellently in systems where space saving, quick response, and low flow resistance are important.

How does a butterfly valve work?

The operating principle of a butterfly valve is based on a rotating disc centrally positioned in the pipeline. The disc is connected to a stem that can be operated manually (using a lever or handwheel), pneumatically, or electrically. When the disc is aligned parallel to the flow, the medium flows freely. When rotated 90°, the flow is completely blocked.

Unlike ball valves, butterfly valves can also function as control valves, allowing partial opening to regulate flow, making them a highly versatile solution.

Advantages of butterfly valves

Butterfly valves offer many practical benefits:

Compact design – occupy little space and are lightweight

Quick opening/closing – full disc rotation of 90°

Flow regulation capability – suitable for both ON/OFF operation and partial opening

Low installation and maintenance costs – simple construction and long service life

Wide range of applications – suitable for water, air, steam, oils, acids, and other media

Available in wafer, lug, and flanged versions – adaptable to different piping systems

Applications of butterfly valves

Butterfly valves are used in:

Water supply and sewage networks

HVAC installations (heating, ventilation, air conditioning)

Chemical and petrochemical industries

Power plants and district heating systems

Food and pharmaceutical industries

Compressed air and technical gas systems

Summary

Butterfly valves are reliable, economical, and versatile valves for flow shut-off and regulation in a variety of industrial installations. Thanks to their simplicity, fast operation, and availability in many design variants, they are widely chosen both in new projects and when modernizing existing systems.

Models and production range of Zondex butterfly valves

Zondex Engineering offers a wide range of butterfly valve models, including the following models:

301, 302, 303, 304, 305, 306, 307, 308, 309, 310, 311.

Available nominal diameters: DN 50 to DN 2000

Working pressure range: PN 6 (0.6 MPa) to PN 100 (10.0 MPa)

Valve bodies can be manufactured in various materials depending on the application:

🔹 Ductile iron

– EN-GJS-400-15 / GGG40

🔹 Carbon steels

– ASTM A216 WCB, A105, Q235 / P235, A216 WCC

🔹 Low alloy steels

– ASTM A352 LCC, LCB, LCI, LC2

– ASTM A217 WC6, WC9

– ASTM A182 F11

– ASTM A350 LF1 / LF2 / LF3

🔹 Stainless steels (corrosion-resistant)

– A351 CF8 / AISI 304 / A182 F304

– A351 CF8M / AISI 316 / A182 F316

– A351 CF3 / AISI 304L / A182 F304L

– A351 CF3M / AISI 316L

– AISI 904L, AISI 316Ti, AISI 321, AISI 310S

🔹 Special steels (duplex)

– Duplex 2205

– Duplex 2507