What is a knife gate valve?

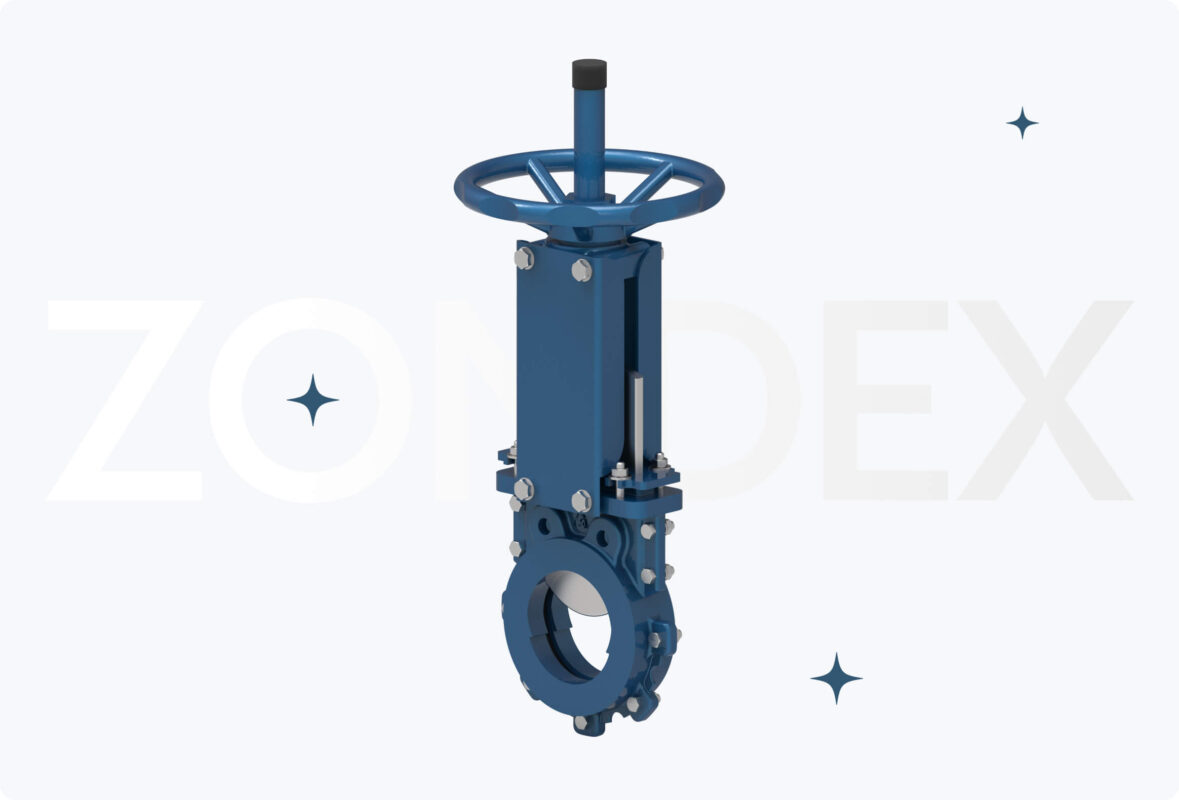

A knife gate valve is a specialized shut-off valve designed for use with fluids containing solids, sludge, mud, or suspensions. Its key component is a thin, sharp-edged gate that acts like a knife, slicing through the medium to enable quick flow shut-off.

Knife gate valves are widely used in the pulp and paper industry, wastewater treatment plants, mining, chemical, and food industries—essentially in applications where conventional valves might clog or wear out too quickly.

How does a knife gate valve work?

A knife gate valve operates by vertically moving a thin, sharp-edged gate plate within the valve body. When the plate is lowered, it slices through solids and suspensions in the medium, reliably blocking the flow. When the plate is raised, it creates a free flow path with minimal pressure loss.

Operation can be manual, using a handwheel or lever, or automatic via pneumatic, hydraulic, or electric actuators. Due to its design, the knife gate valve is especially suitable for abrasive, viscous, and solids-laden media.

Advantages of knife gate valves

Knife gate valves offer a number of significant advantages:

- Adapted for challenging media – excel at handling contaminated fluids, sediments, sludge, and granulates

- Compact design – occupy less space compared to traditional wedge gate valves

- Low flow resistance – the valve opening ensures almost full bore flow of the medium

- Easy maintenance – simple construction facilitates servicing and seal replacement

- Wear and corrosion resistance – modern materials and coatings provide extended service life

Applications of knife gate valves

Knife gate valves are primarily used in:

- Wastewater treatment plants and industrial sewage systems

- Pulp and paper industry

- Mining and slurry transportation systems

- Food processing industry (e.g., vegetable and fruit processing)

- Chemical and petrochemical plants

Summary

Knife gate valves are indispensable solutions in installations handling contaminated, aggressive, or solids-laden media. Thanks to their compact design, durability, and ease of operation, they find application in many demanding industrial sectors. By choosing Zondex knife gate valves, you invest in efficiency, longevity, and operational safety of your installations.

Models and production range of Zondex knife gate valves

Zondex Engineering offers a wide range of knife gate valve models, including the following series:

201M, 202M, 203M, 204M, 205M, 206M, 201P, 202P, 203P, 204P.

Available nominal diameters: DN 50 to DN 1200

Working pressure range: PN 10 (1.0 MPa) to PN 16 (1.6 MPa)

Valve bodies can be manufactured from various materials depending on the application:

🔹 Ductile iron

– EN-GJS-400-15 / GGG40

🔹 Carbon steels

– ASTM A216 WCB, A105, Q235 / P235, A216 WCC

🔹 Low alloy steels

– ASTM A352 LCC, LCB, LCI, LC2

– ASTM A217 WC6, WC9

– ASTM A182 F11

– ASTM A350 LF1 / LF2 / LF3

🔹 Stainless steels (corrosion-resistant)

– A351 CF8 / AISI 304 / A182 F304

– A351 CF8M / AISI 316 / A182 F316

– A351 CF3 / AISI 304L / A182 F304L

– A351 CF3M / AISI 316L

– AISI 904L, AISI 316Ti, AISI 321, AISI 310S

🔹 Special steels (duplex)

– Duplex 2205

– Duplex 2507