Butterfly Valve 307

Technical Specifications

- Nominal diameter DN 50-1200

- Nominal pressure PN10, PN16

- Medium temperature -60 °C ... +180 °C

- Types of Valve End Connections Flanged, wafer

- Leakage Class «А»

- Mounting Position Any, except for downward-driven devices

- Types of Control — manual (lever) — manual (handwheel)— manual (gearbox)— pneumatic actuation — electric actuation

- Warranty Period 12 months

- Average Service Life 10 000 cycles

- Guaranteed Service Life Not less than 5000 cycles

Technical Drawings and Dimensions

Table of Basic Dimensions

| DN | D1, mm | L, mm | n-ød |

|---|---|---|---|

| 50 | 160 | 43 | 4-M16 |

| 65 | 180 | 46 | 4-M16 |

| 80 | 195 | 46 | 8-M16 |

| 100 | 215 | 52 | 8-M16 |

| 125 | 245 | 56 | 8-M16 |

| 150 | 280 | 56 | 8-M20 |

| 200 | 335 | 60 | 12-M20 |

| 250 | 405 | 68 | 12-M24 |

| 300 | 460 | 78 | 12-M24 |

| 350 | 520 | 78 | 16-M24 |

| 400 | 580 | 102 | 16-M27 |

| 450 | 640 | 114 | 20-M27 |

Tabulated values for diameters DN500–DN1200 are available upon request

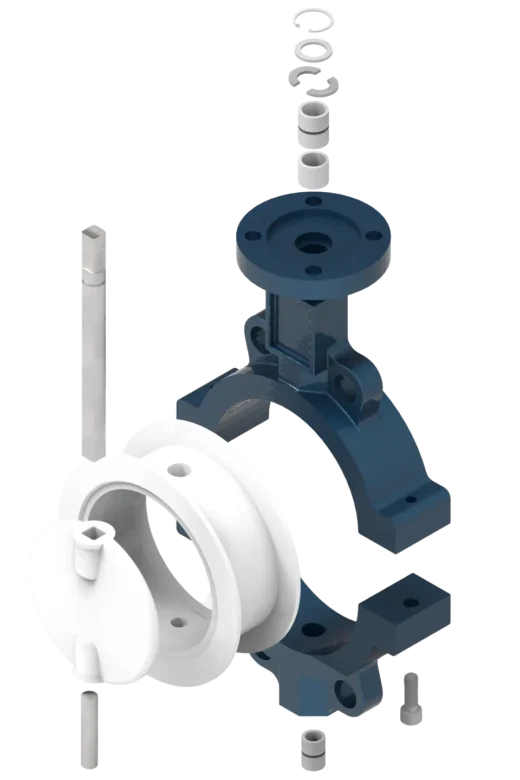

Product Description

Butterfly Valve – Model 307 is designed for regulating and shutting off the flow of working media.

A key feature of this valve is the use of a PTFE seal, which provides high resistance to chemically aggressive media. The valve body is of a split type (two body parts connected by bolts), which facilitates servicing and seal replacement, and extends the device’s service life.

Design features of the model:

- High chemical resistance of the seal and disc to chemically aggressive environments

- Leakage class “A”

- Split body design for easy maintenance and seal replacement

Sealing materials:

🔹 PTFE, FEP, PO, PFA

Valve bodies can be manufactured from various materials depending on the application:

🔹 Carbon steels

A216 WCB (1.0619, GP240GH)

Discs can be made of the following materials:

AISI 316 + PTFE / FEP / PO / PFA

AISI 304 + PTFE / FEP / PO / PFA

A216 WCB + PTFE / FEP / PO / PFA

Ask them to us!

form below and send

your application to the following e-mail address