Globe valve 601

DN15-500, PN16-420

Guarantee

Comprehensive Documentation

Shipping

Technical Specifications

- Nominal diameter DN 15-500

- Nominal pressure PN16, PN25, PN40, PN63, PN100, PN160, PN250, PN320, PN400, PN420

- Medium temperature -196 °C ... +540 °C

- Types of Valve End Connections Welded, Flanged

- Leakage Class «А»

- Warranty Period 12 months

- Mounting Position Any, except for downward-driven devices

- Types of Control — manual (lever) — manual (handwheel) — pneumatic actuation — electric actuation

- Average Service Life 10 000 cycles

- Guaranteed Service Life Not less than 5000 cycles

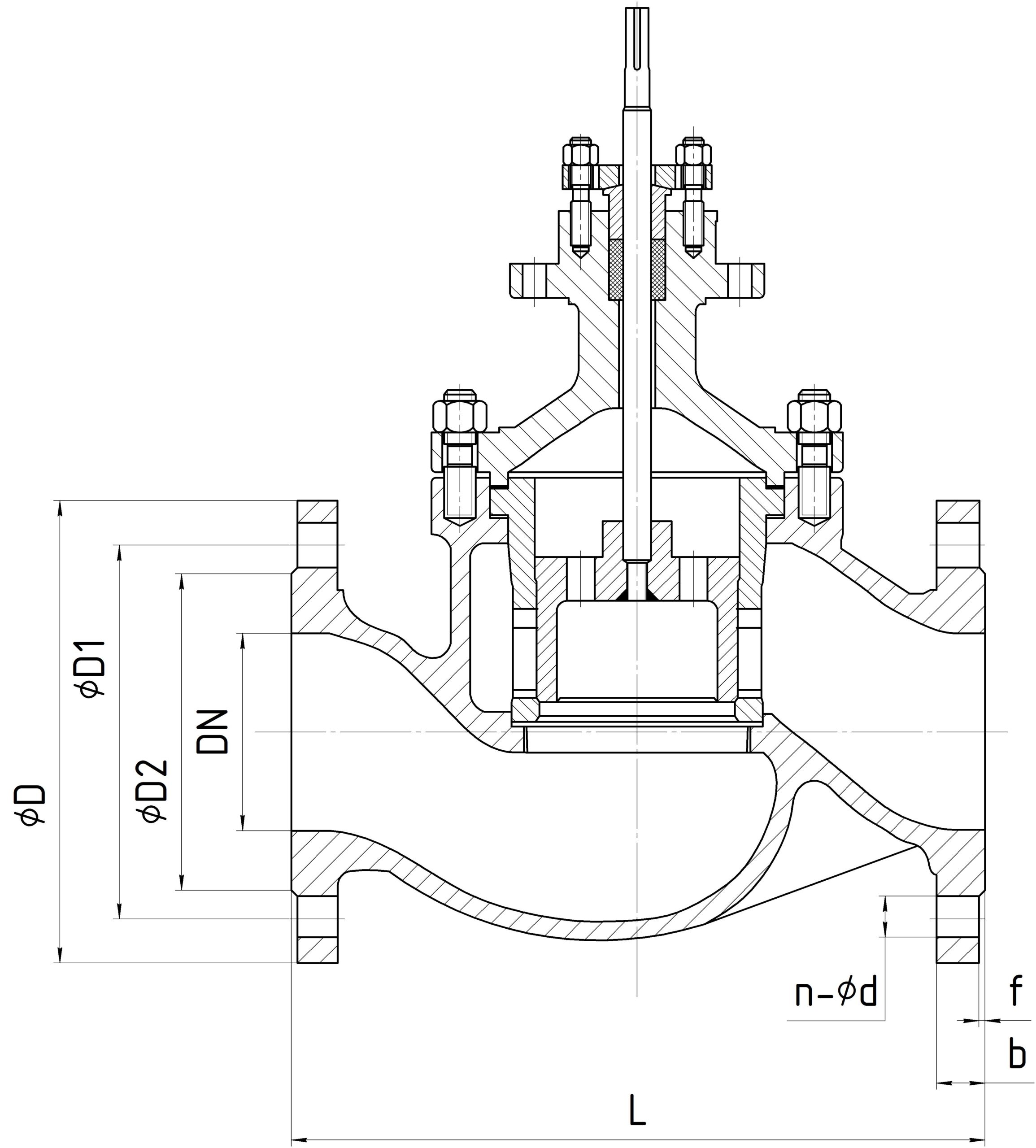

Technical Drawings and Dimensions

Nominal diameter PN16

Table of Basic Dimensions

| DN, mm | D, mm | D1, mm | D2, mm | L, mm | b, mm | f, mm | n-ød, mm |

|---|---|---|---|---|---|---|---|

| 15 | 95 | 65 | 45 | 130 | 14 | 2 | 4-14 |

| 20 | 105 | 75 | 58 | 150 | 14 | 2 | 4-14 |

| 25 | 115 | 85 | 68 | 160 | 14 | 2 | 4-14 |

| 32 | 140 | 100 | 78 | 180 | 16 | 2 | 4-18 |

| 40 | 150 | 110 | 88 | 200 | 16 | 3 | 4-18 |

| 50 | 165 | 125 | 102 | 230 | 16 | 3 | 4-18 |

| 65 | 185 | 145 | 122 | 290 | 18 | 3 | 4-18 / 8-18 |

| 80 | 200 | 160 | 138 | 310 | 20 | 3 | 8-18 |

| 100 | 220 | 180 | 158 | 350 | 20 | 3 | 8-18 |

| 125 | 250 | 210 | 188 | 400 | 22 | 3 | 8-18 |

| 150 | 285 | 240 | 212 | 480 | 24 | 3 | 8-22 |

| 200 | 340 | 295 | 268 | 600 | 26 | 3 | 12-22 |

| 250 | 405 | 355 | 320 | 650 | 30 | 3 | 12-26 |

| 300 | 460 | 410 | 378 | 750 | 30 | 4 | 12-26 |

| 350 | 520 | 470 | 438 | 850 | 34 | 4 | 16-26 |

| 400 | 580 | 525 | 490 | 980 | 36 | 4 | 16-30 |

| 450 | 640 | 585 | 550 | 1100 | 40 | 4 | 20-30 |

| 500 | 715 | 660 | 610 | 1150 | 44 | 4 | 20-33 |

Product Description

Globe valve model 601 is designed for flow control and shut-off in systems requiring high tightness and durability. Thanks to a wide selection of body and gasket materials, model 601 can be adapted to various operating conditions, including chemically aggressive media and high-temperature applications.

Design features of the model:

- Designed for high-pressure applications

- Wide selection of body, gasket, and sealing insert materials

- Reinforced bonnet design with ribs, allowing operation in both cryogenic and high-temperature conditions

Working media:

- Aggressive and non-aggressive liquids

- Petroleum products

- Alkalis

- Acids

- Water, steam

Body / disc materials:

🔹 Carbon steels

- A216 WCB (1.0619, GP240GH)

- A216 WCC (1.1131)

🔹 Low-alloy steels

- A352 LCC (~1.6220/16MnMo5)

- A352 LCB (~P355NL1/1.0566), LC1

- A217 WC6 (1.7363/13CrMo4-5)

🔹 Stainless steels (corrosion-resistant)

- A351 CF8 (1.4308) / AISI 304 / A182 F304 (1.4301)

- A351 CF8M (1.4408) / AISI 316 / A182 F316 (1.4401)

- A351 CF3 (1.4306) / AISI 304L / A182 F304L

- A351 CF3M (1.4409) / AISI 316L (1.4404)

- AISI 904L (1.4539)

- AISI 316Ti (1.4571)

Leave a request

Do you still have questions?

Ask them to us!

Ask them to us!

Contact our specialists by phone or write to us on instant messaging platforms.

Use the

form below and send

your application to the following e-mail address

form below and send

your application to the following e-mail address