Knife Gate Valve 103

DN50-1000 PN10-16

Guarantee

Comprehensive Documentation

Shipping

Technical Specifications

- Nominal diameter DN 50-1000

- Nominal pressure PN 10, PN16

- Medium temperature -20 °C ... +130 °C

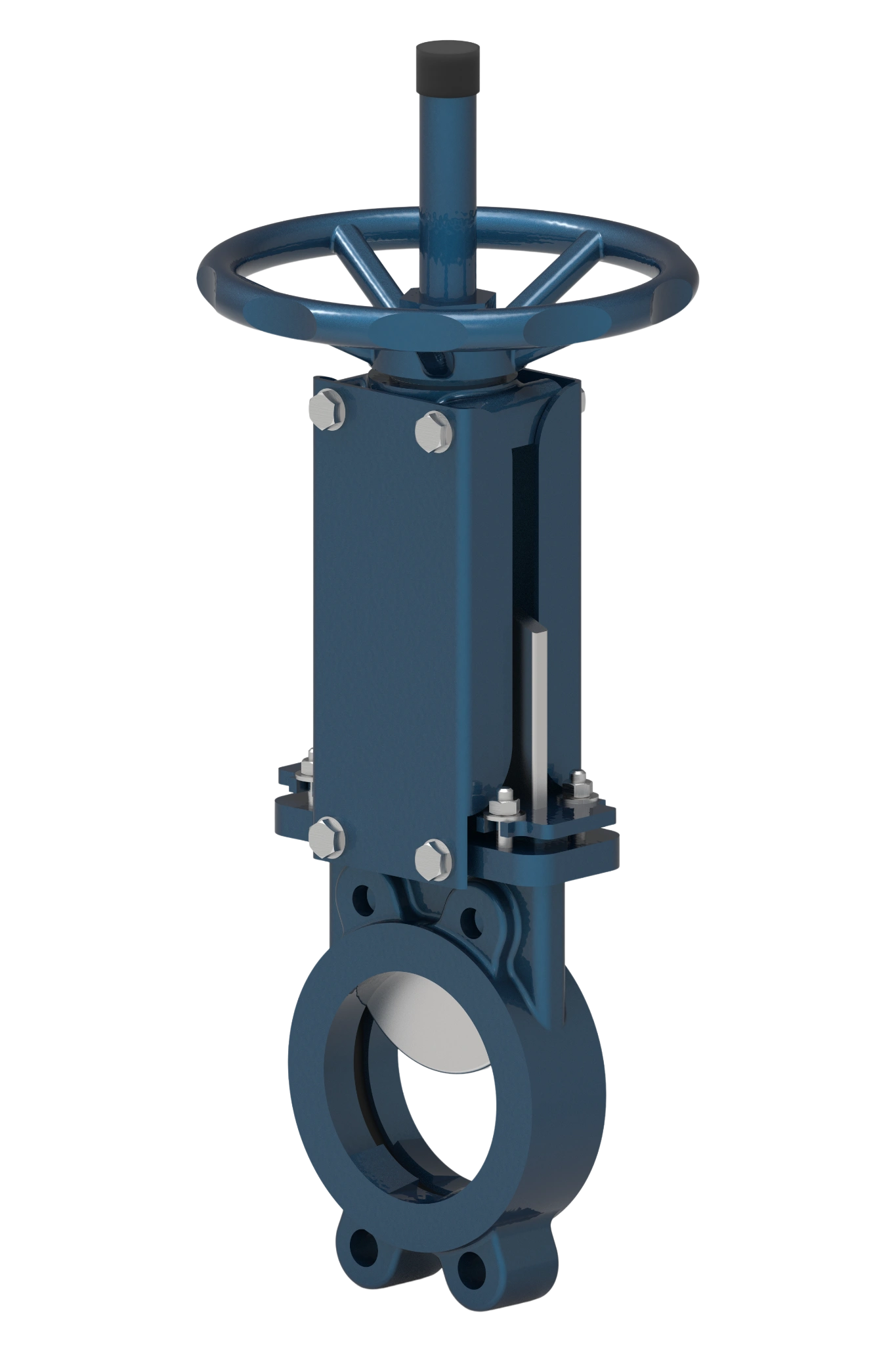

- Types of Valve End Connections Wafer, lug

- Leakage Class «А»

- Mounting Position Any, except for the actuator facing downward

- Types of Control — manual (lever) — manual (handwheel)— manual (gearbox)— pneumatic actuation — electric actuation

- Warranty Period 12 months

- Average Service Life 2500 cycles

- Guaranteed Service Life Not less than 1000 cycles

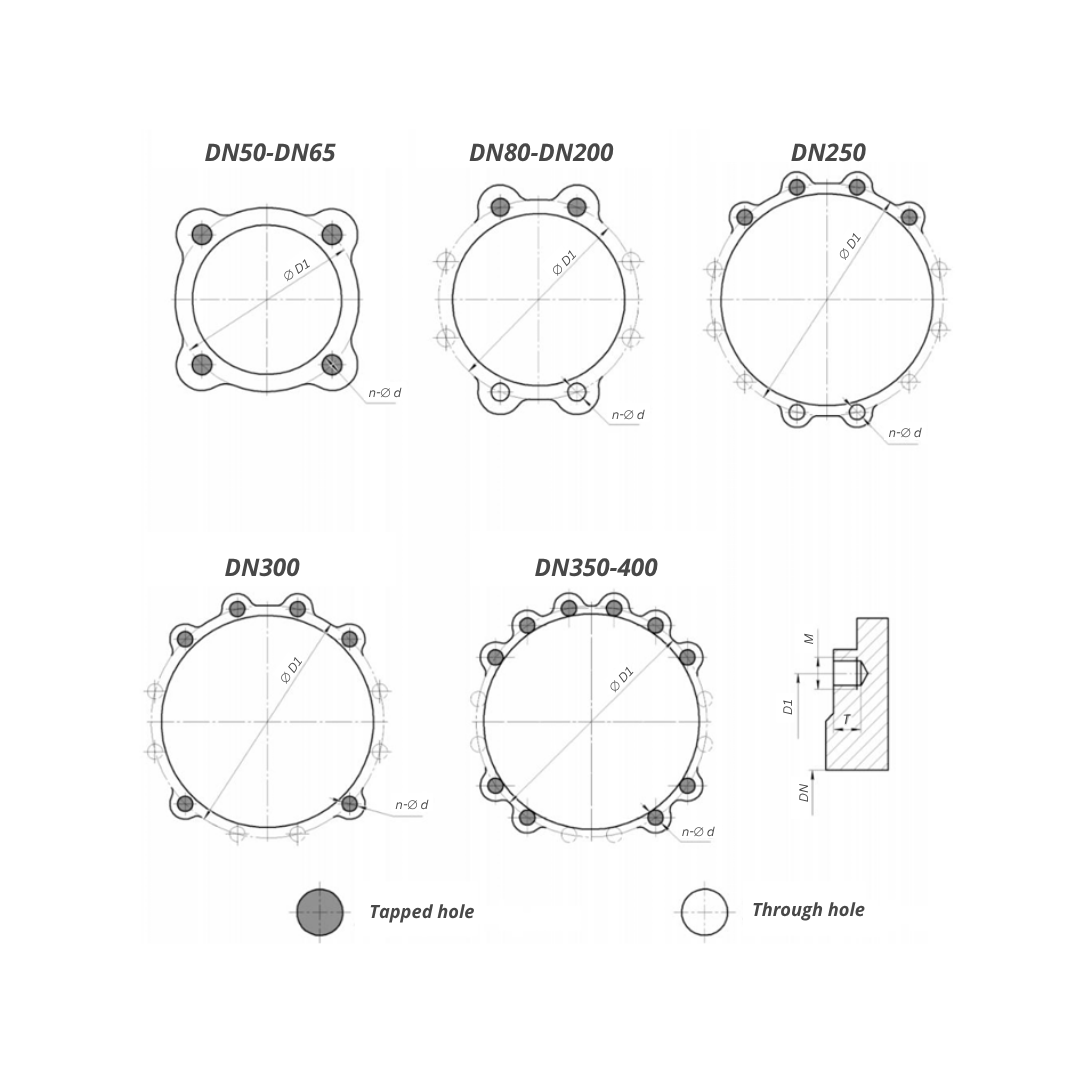

Technical Drawings and Dimensions

Nominal Pressure PN10

Basic Dimensions Table

| DN | D, mm | D1, mm | D2, mm | L, mm | n-ød |

|---|---|---|---|---|---|

| 50 | 165 | 125 | 102 | 48 | 4-M16 |

| 65 | 185 | 145 | 122 | 48 | 4-M16 / 8-M16 |

| 80 | 200 | 160 | 138 | 51 | 8-M16 |

| 100 | 220 | 180 | 158 | 51 | 8-M16 |

| 125 | 250 | 210 | 188 | 57 | 8-M16 |

| 150 | 285 | 240 | 212 | 57 | 8-M20 |

| 200 | 340 | 295 | 268 | 70 | 8-M20 |

| 250 | 395 | 350 | 320 | 70 | 12-M20 |

| 300 | 445 | 400 | 370 | 76 | 12-M20 |

| 350 | 505 | 460 | 430 | 76 | 16-M20 |

| 400 | 565 | 515 | 482 | 89 | 16-M24 |

| 450 | 615 | 565 | 532 | 89 | 20-M24 |

| 500 | 670 | 620 | 585 | 114 | 20-M24 |

| 600 | 780 | 725 | 685 | 114 | 20-M27 |

Tabular values for diameters DN700–DN1400 and for pressure PN16 are available upon request

Product Description

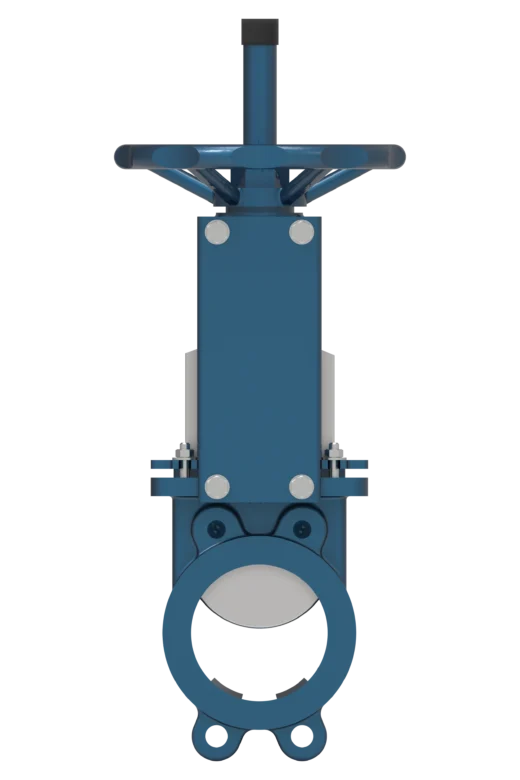

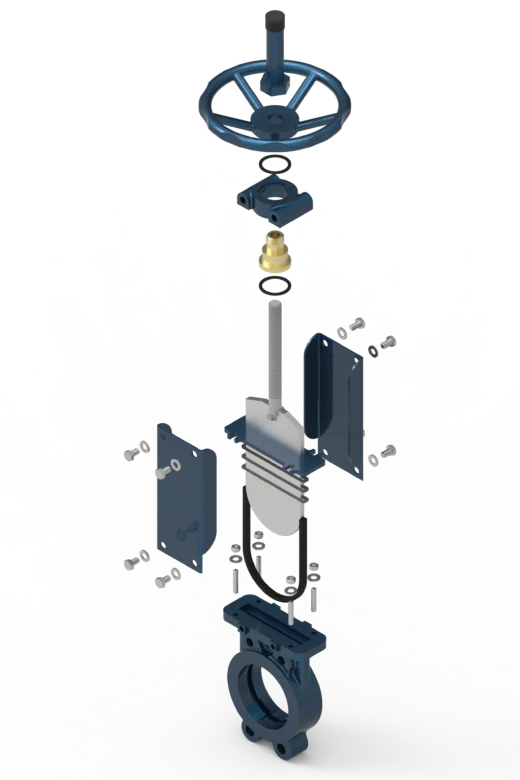

Knife Gate Valve Model 103 is manufactured as a monolithic casting (non-dismountable) and equipped with a U-shaped seat.

During valve opening, the seal adapts to the internal contour of the body, ensuring a full bore flow path without stagnation zones. This provides effective protection against the ingress of fine abrasive particles into the valve’s “gate pocket,” which guarantees high cycle life and operational durability.

Design Features:

- Articulated seal providing bi-directional tightness

- Wide selection of body and sealing materials

- During valve opening, the seal conforms to the shape of the internal body cross-section, ensuring unrestricted, full bore flow and eliminating stagnation zones

Working Media:

- Water, steam, condensate

- Alkalis

- Acids

- Abrasive contaminants

- High-temperature gases

- Petroleum products

Body Materials:

🔹 Ductile Iron

EN-GJS-400-15 / GGG40

Seat Materials:

- EPDM

- NBR

- FKM (Viton)

- Metal-to-metal

Leave a request

Do you still have questions?

Ask them to us!

Ask them to us!

Contact our specialists by phone or write to us on instant messaging platforms.

Use the

form below and send

your application to the following e-mail address

form below and send

your application to the following e-mail address