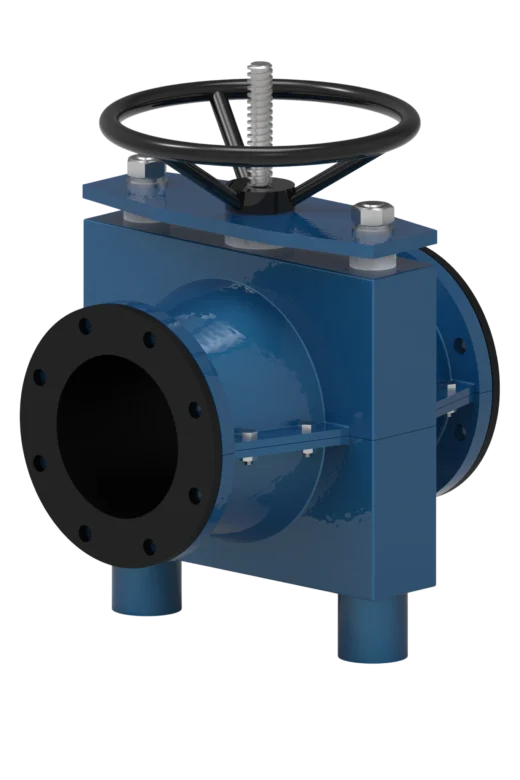

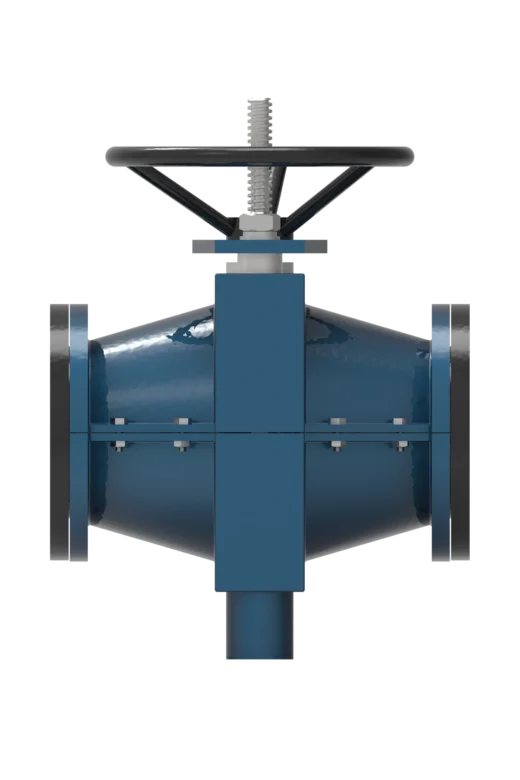

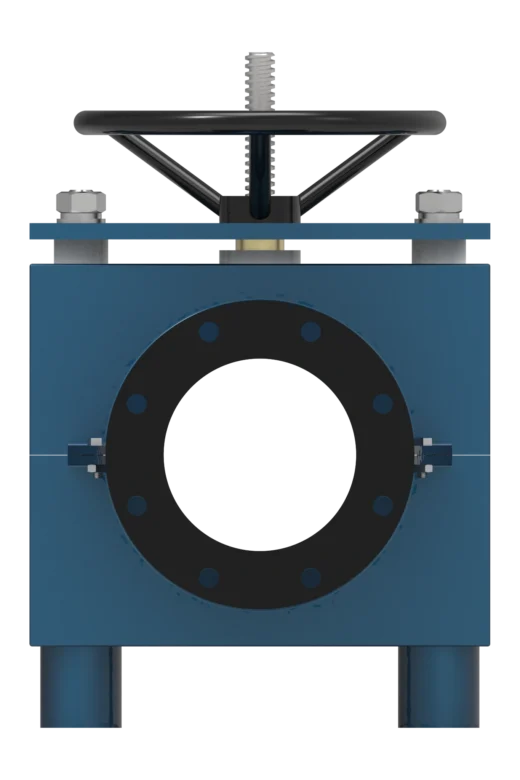

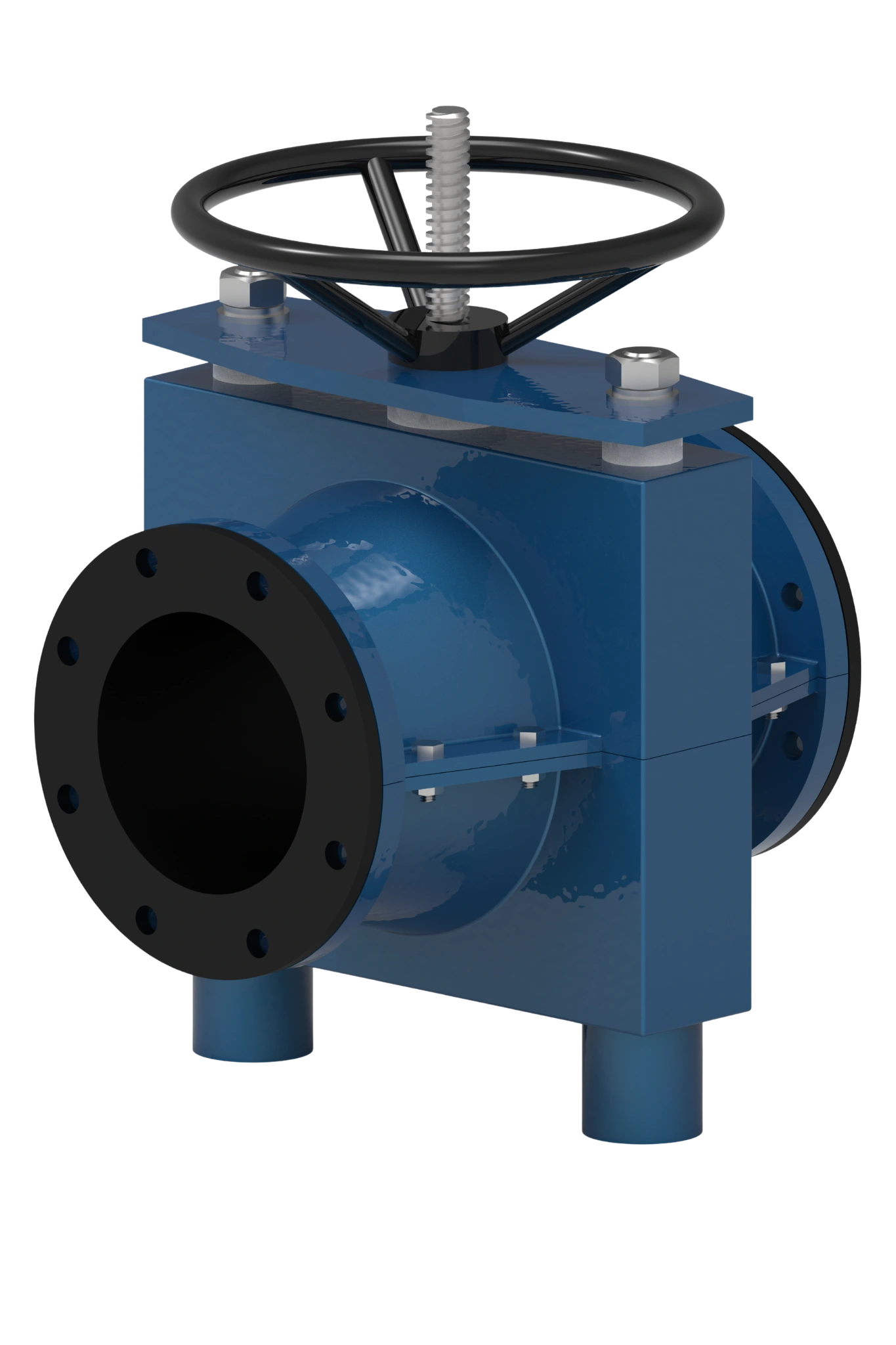

Pinch Valve (Hermetically Closed) 205M

Technical Specifications

- Nominal diameter DN 50-1200

- Nominal pressure PN10, PN16, PN25, PN40

- Medium temperature -60 °C ... +200 °C

- Body type Closed Hermetic

- Leakage Class «А»

- Mounting Position Any, except for downward-driven devices

- Types of Control — manual (lever) — manual (handwheel)— manual (gearbox)— pneumatic actuation — electric actuation

- Warranty Period 12 months

- Average Service Life 6 000 cycles

- Guaranteed Service Life Not less than 4000 cycles

Technical Drawings and Dimensions

Basic Dimensions Table

| DN | D, mm | D1, mm | L, mm | n-ød |

|---|---|---|---|---|

| 50 | 165 | 125 | 165 | 4-M18 |

| 65 | 185 | 145 | 165 | 8-M18 |

| 80 | 200 | 160 | 200 | 8-M18 |

| 100 | 220 | 180 | 250 | 8-M18 |

| 125 | 250 | 210 | 310 | 8-M18 |

| 150 | 285 | 240 | 375 | 8-M22 |

| 200 | 340 | 295 | 500 | 8-M22 |

| 250 | 395 | 350 | 625 | 12-M22 |

| 300 | 445 | 400 | 750 | 12-M22 |

| 350 | 505 | 460 | 875 | 16-M22 |

| 400 | 565 | 515 | 1000 | 16-M26 |

| 450 | 615 | 565 | 1125 | 20-M26 |

| 500 | 670 | 620 | 1250 | 20-M26 |

| 600 | 780 | 725 | 1500 | 20-M30 |

Tabular values for diameters DN700–DN1200 and for pressure PN16 are available upon request

Product Description

Pinch Valves Model 205M are designed for regulating and isolating highly abrasive media.

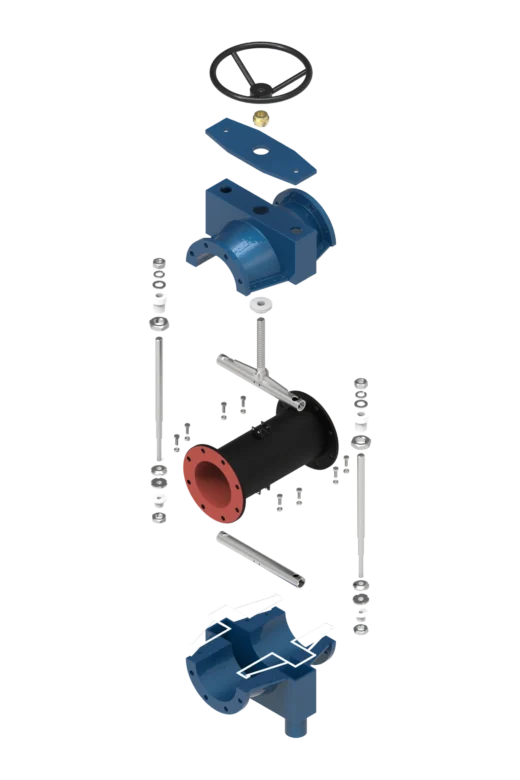

Key advantages of the valve include a dismountable two-piece body and a double-sided hose sleeve compression mechanism. The closed, sealed body ensures valve tightness even in the event of hose sleeve failure.

Design Features:

- Dismountable body

- Stretching straps for hose sleeve

- Dual-sided sleeve compression

- Quick and easy hose sleeve replacement

- Hermetically sealed housing

Recommended for Use In:

Chemical industry:

Handling of corrosive and abrasive materials, powder and solid transport, disposal of process wasteMining and raw material processing:

Slurry from metal ores, mineral suspensions, quartz sand, flotation and dewatering sludges, abrasive and corrosive media in processingWastewater treatment systems:

Sand and sludge handling, raw sewage, lime and coal slurry transportPulp & paper industry and others:

Wherever media contain solids or have abrasive characteristics

Operating Media:

- Highly abrasive environments

- Chemically aggressive environments

- Alkalis

- Acids

- Water with abrasive particles

- Salt solutions

- Coal

- Sand

- Polar solvents

- Silicone oils

- Media containing fuel oil, crude oil, gasoline

Body Materials:

🔹Ductile iron:

- EN-GJS-400-15 / GGG40

🔹Carbon steels:

- A216 WCB (1.0619, GP240GH)

🔹Corrosion-resistant stainless steels:

- A351 CF8 (1.4308) / AISI 304 / A182 F304 (1.4301)

- A351 CF8M (1.4408) / AISI 316 / A182 F316 (1.4401)

🔹Aluminum

Material of the Flexible Hose (Rubber Sleeve):

| Material | Temperature Range | Properties / Applications |

|---|---|---|

| EPDM | -50 °C to +130 °C | Weak acids and alkalis, salt solutions, contaminated water, sand, mildly abrasive media |

| NR (Natural Rubber) | -40 °C to +80 °C | Highly abrasive media, sand-laden water, coal, slurries |

| NBR (Nitrile Rubber) | -40 °C to +120 °C | Abrasive media, contaminated water, crude oil, fuel oil, gasoline, oils |

| CSM (Hypalon) | -40 °C to +130 °C | Abrasive and chemically aggressive media, contaminated water |

| IIR (Butyl) | -50 °C to +130 °C | Abrasive media, polar solvents, silicone oils, contaminated water |

| NR + Linatex | -40 °C to +85 °C | Highly wear-resistant, weak acids and alkalis, salt solutions, sand, coal |

| SBR | -40 °C to +100 °C | Abrasive media, contaminated water, glycols, acetone |

| FKM (Viton®) | -20 °C to +150 °C | Chemically aggressive media, solvents, high temperatures, abrasive media |

Ask them to us!

form below and send

your application to the following e-mail address