Gate valve 502

Technical Specifications

- Nominal diameter DN 40-1200

- Nominal pressure PN 6-1000

- Medium temperature -196 °C ... +540 °C

- Types of Valve End Connections Welded, Flanged, Socket

- Leakage Class «А»

- Warranty Period 12 months

- Mounting Position Any, except for downward-driven devices

- Types of Control — manual (lever) — manual (handwheel) — pneumatic actuation — electric actuation

- Average Service Life 10 000 cycles

- Guaranteed Service Life Not less than 5000 cycles

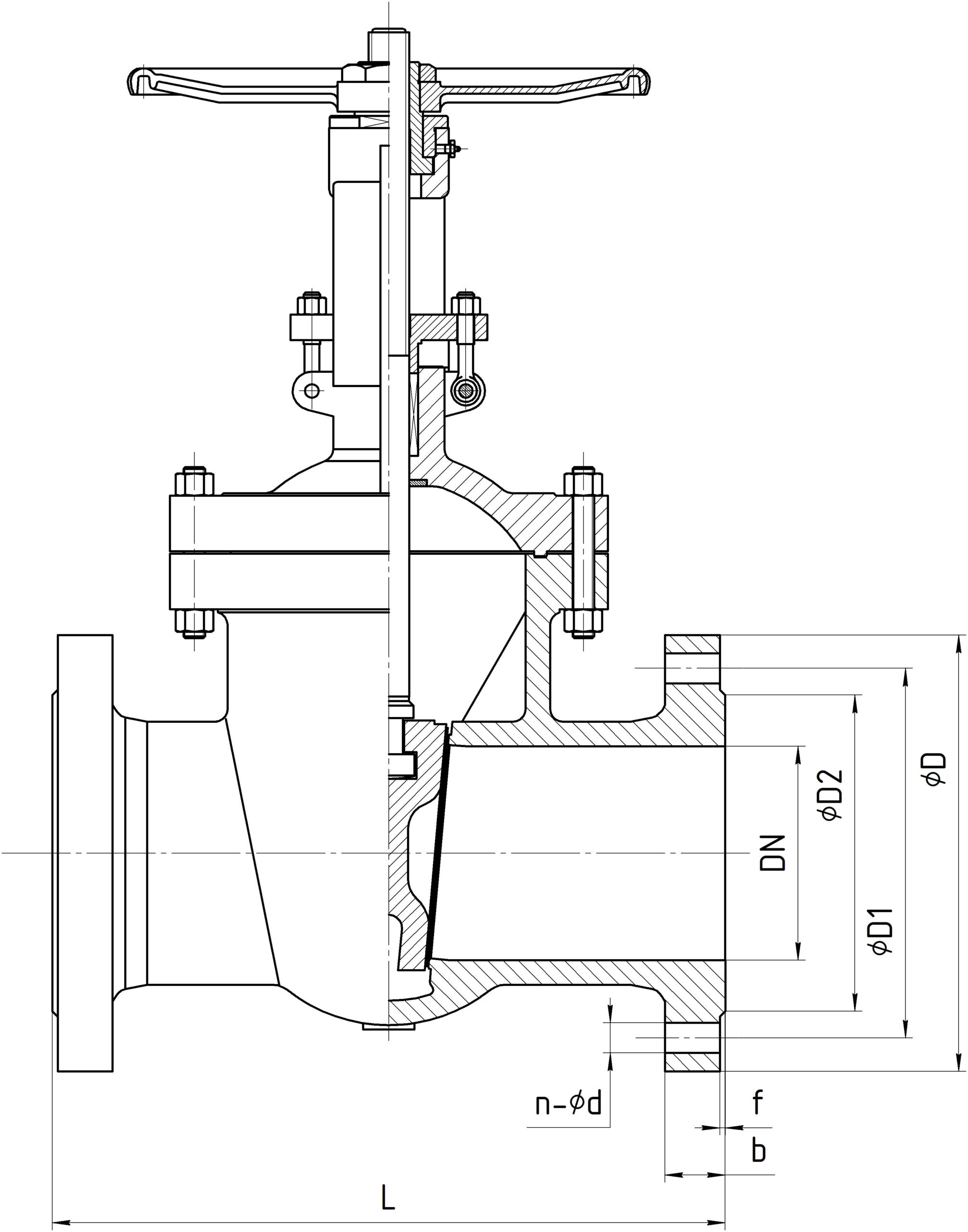

Technical Drawings and Dimensions

Table of Basic Dimensions

| DN, mm | D, mm | D1, mm | D2, mm | L, mm | b, mm | f, mm | n-ød, mm |

|---|---|---|---|---|---|---|---|

| 50 | 165 | 125 | 102 | 250 | 16 | 3 | 4-18 |

| 65 | 135 | 145 | 122 | 270 | 18 | 3 | 4-18 / 8-18 |

| 80 | 200 | 160 | 138 | 280 | 20 | 3 | 8-18 |

| 100 | 220 | 180 | 158 | 300 | 20 | 3 | 8-18 |

| 125 | 250 | 210 | 188 | 325 | 22 | 3 | 8-18 |

| 150 | 285 | 240 | 212 | 350 | 24 | 3 | 8-22 |

| 200 | 340 | 295 | 268 | 400 | 26 | 3 | 12-22 |

| 250 | 405 | 355 | 320 | 450 | 30 | 3 | 12-26 |

| 300 | 460 | 410 | 378 | 500 | 30 | 4 | 12-26 |

| 350 | 520 | 470 | 438 | 550 | 31 | 4 | 16-26 |

| 400 | 580 | 525 | 490 | 600 | 36 | 4 | 16-30 |

| 450 | 640 | 585 | 550 | 650 | 40 | 4 | 20-30 |

| 500 | 715 | 650 | 610 | 700 | 44 | 4 | 20-33 |

Product Description

Wedge gate valve model 502 is designed for regulating and shutting off flow in installations where high tightness and durability are required.

Thanks to a wide selection of body materials and seals, the valves can be precisely adapted to various operating conditions, including contact with chemically aggressive media and operation at high temperatures. The reinforced, ribbed cover construction provides increased mechanical strength and operational stability even under extreme temperature conditions. The possibility to choose between solid and flexible wedges allows optimal adjustment of the valve to the specifics of the particular technological application.

Design features of the model:

- Designed for high-pressure applications

- Wide range of body materials, seals, and sealing inserts

- Reinforced, ribbed cover — suitable for cryogenic and high-temperature conditions

- Option for solid or flexible wedge (depending on operating conditions)

Working medium:

Non-aggressive liquids

(water, steam, mineral oils, glycols, low concentration salt solutions, e.g., NaCl)Aggressive, corrosive or chemically active liquids

(sulfuric acid – H₂SO₄, hydrochloric acid – HCl, industrial wastewater, ammonia – aqueous or anhydrous)Petroleum products and fuels

(crude oil, gasoline, oil, liquid fuels)Technical and industrial gases

(hydrogen – H₂, hydrogen sulfide – H₂S, biogas)

Body materials:

🔹 Carbon steels

- ASTM A216 WCB (1.0619, GP240GH)

🔹 Low-temperature carbon steels

- A352LCB / A352LCC

🔹 Special-purpose alloy steels

- ASTM A217 WC6 / WC9

🔹 Stainless steels (corrosion resistant)

- ASTM A351 CF8 (1.4308) / AISI 304 / A182 F304 (1.4301)

- ASTM A351 CF8M (1.4408) / AISI 316 / A182 F316 (1.4401)

- A351 CF3 (1.4306) / AISI 304L / A182 F304L

- A351 CF3M (1.4409) / AISI 316L (1.4404)

- AISI 316Ti (1.4571)

- AISI 904L (1.4539)

Ask them to us!

form below and send

your application to the following e-mail address