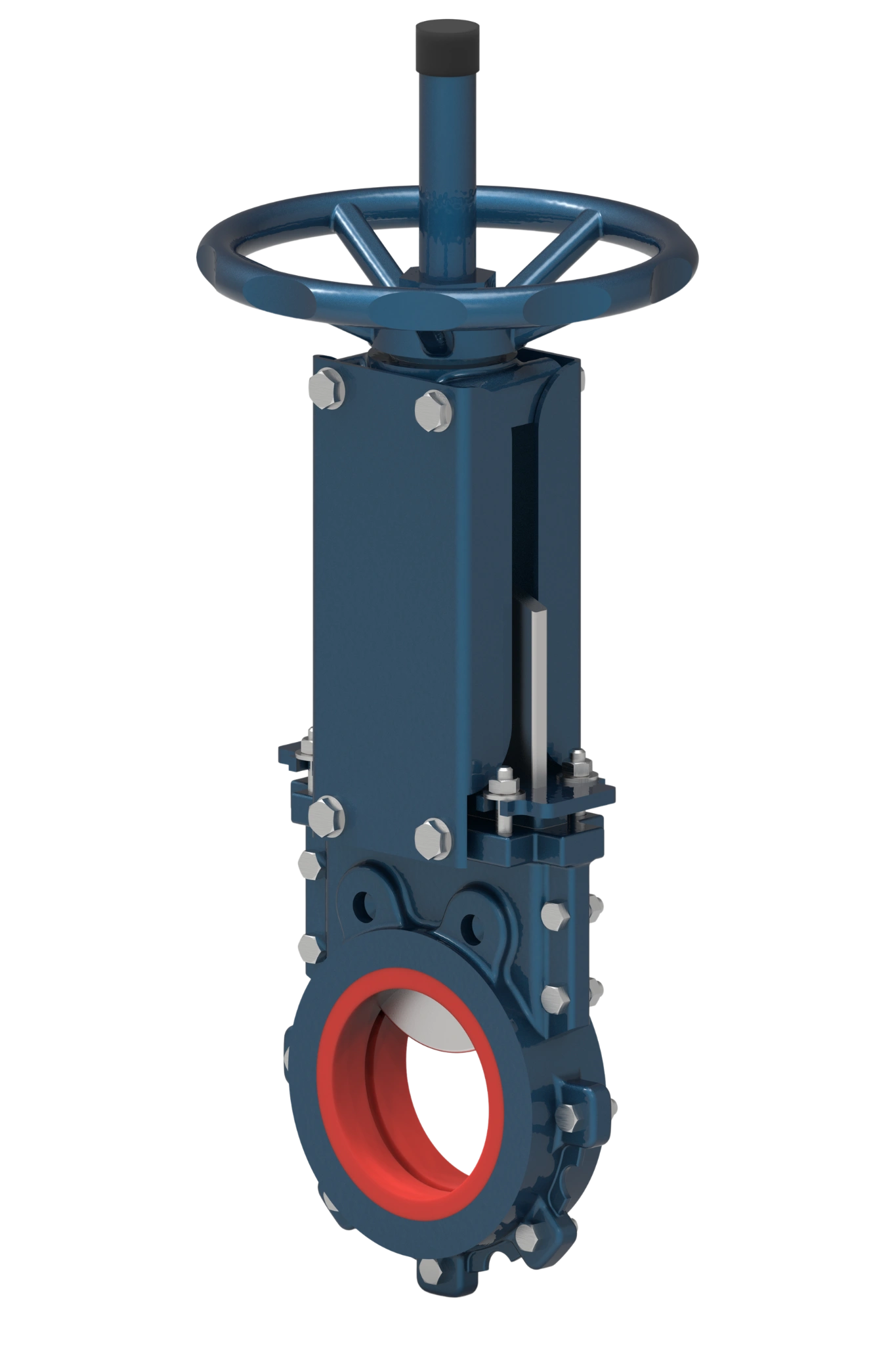

Knife Gate Valve 108

DN50-800 PN10-16

Guarantee

Comprehensive Documentation

Shipping

Technical Specifications

- Nominal diameter DN 50-800

- Nominal pressure PN 6-16

- Medium temperature -20 °C ... +100 °C

- Types of Valve End Connections Welded, Socket

- Leakage Class «А»

- Mounting Position Any, except for downward-driven devices

- Types of Control — manual (lever) — manual (handwheel)— manual (gearbox)— pneumatic actuation — electric actuation

- Warranty Period 12 months

- Average Service Life 2500 cycles

- Guaranteed Service Life Not less than 1000 cycles

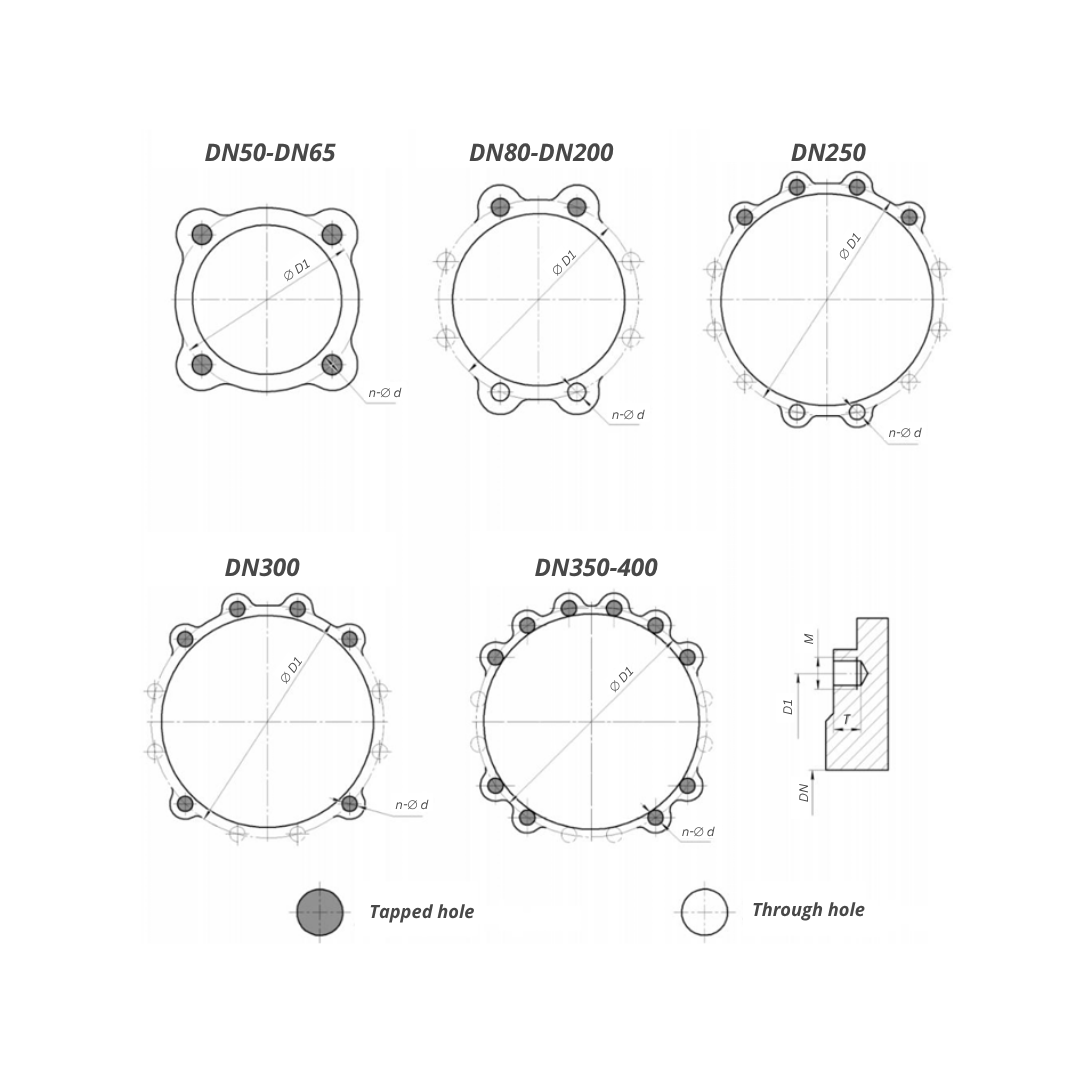

Technical Drawings and Dimensions

Nominal Pressure PN10

Basic Dimensions Table

| DN | D, mm | D1, mm | D2, mm | L, mm | n-ød |

|---|---|---|---|---|---|

| 50 | 165 | 125 | 102 | 48 | 4-M16 |

| 65 | 185 | 145 | 122 | 48 | 4-M16 / 8-M16 |

| 80 | 200 | 160 | 138 | 51 | 8-M16 |

| 100 | 220 | 180 | 158 | 51 | 8-M16 |

| 125 | 250 | 210 | 188 | 57 | 8-M16 |

| 150 | 285 | 240 | 212 | 57 | 8-M20 |

| 200 | 340 | 295 | 268 | 70 | 8-M20 |

| 250 | 395 | 350 | 320 | 70 | 12-M20 |

| 300 | 445 | 400 | 370 | 76 | 12-M20 |

| 350 | 505 | 460 | 430 | 76 | 16-M20 |

| 400 | 565 | 515 | 482 | 89 | 16-M24 |

| 450 | 615 | 565 | 532 | 89 | 20-M24 |

Tabular values for diameters DN500–DN800 and for pressure PN16 are available upon request

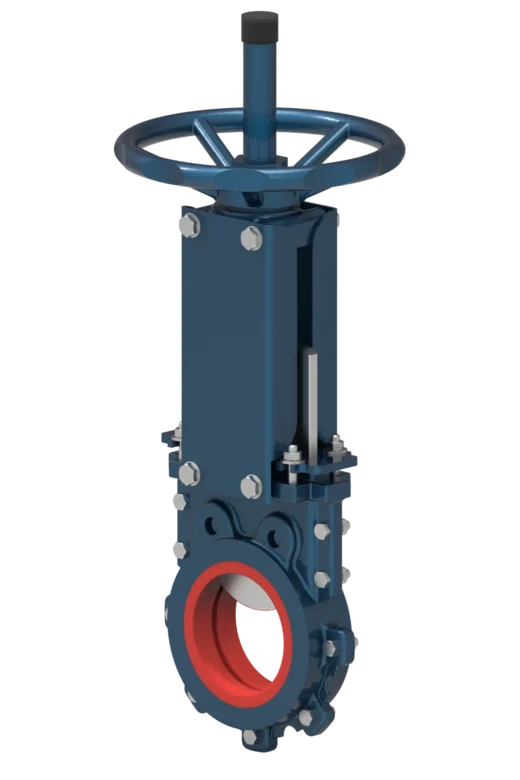

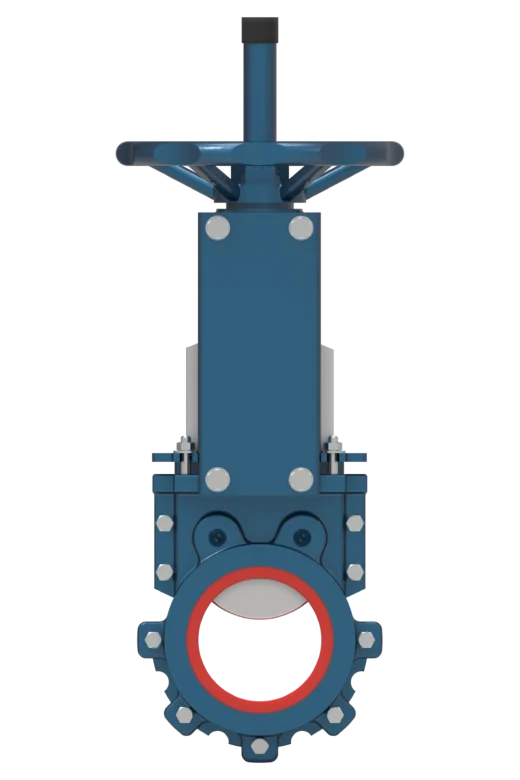

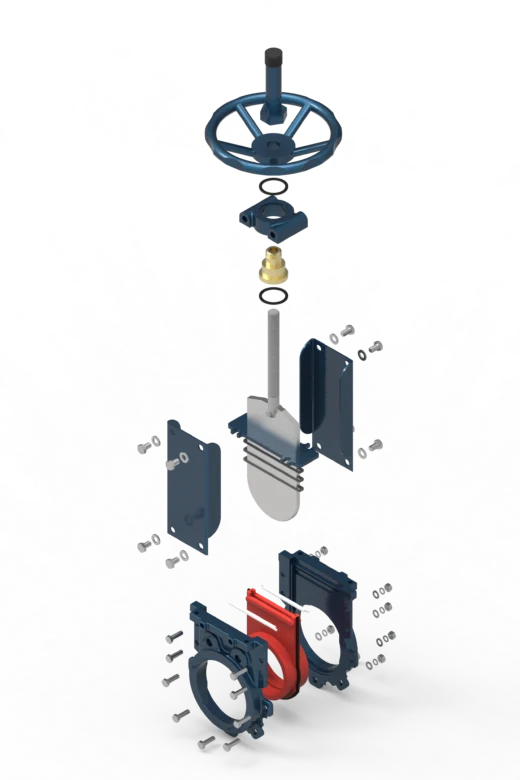

Product Description

Knife gate valve model 108 has a two-piece body and sealing made of polyurethane.

This design allows the valve to be used in environments with a high content of abrasive particles and significantly extends maintenance intervals. The valve geometry ensures free flow of the working medium without stagnation zones, eliminating the risk of abrasive particle accumulation in the lower part of the body.

Design features of the model:

- Monolithic polyurethane sealing at the end, double-sided tightness

- Detachable, two-piece body

- Full flow

- High resistance of the valve to environments with high abrasive content thanks to the “PU” sealing and the lack of contact between the working medium and the valve body

Operating media:

- Water, steam, condensate

- Alkalis

- Acids

- Abrasive contaminants

- High-temperature gases

- Petroleum products

Body material options:

🔹 Ductile iron

- EN-GJS-400-15 / GGG40

🔹 Carbon steels

- A216 WCB (1.0619, GP240GH)

🔹 Stainless steels (corrosion resistant)

- A351 CF8 (1.4308) / AISI 304 / A182 F304 (1.4301)

- A351 CF8M (1.4408) / AISI 316 / A182 F316 (1.4401)

- A351 CF3 (1.4306) / AISI 304L / A182 F304L

- A351 CF3M (1.4409) / AISI 316L (1.4404)

- AISI 316Ti (1.4571)

🔹Special steels (duplex steels)

- Duplex 2205 (UNS S31803/S32205, 1.4462)

- Super Duplex 2507 (UNS S32750 / 1.4410)

Seat material:

- PU

Leave a request

Do you still have questions?

Ask them to us!

Ask them to us!

Contact our specialists by phone or write to us on instant messaging platforms.

Use the

form below and send

your application to the following e-mail address

form below and send

your application to the following e-mail address